About FESTO

|

| Established in 1925, Festo is the world’s leading supplier of automation technology and technical education, deploying its products and services to meet the challenge of smart production for the future in the course of digitalisation. The company also relies on artificial intelligence and machine learning. |

| |

| |

|

|

| |

.jpg) |

| Pneumatic Actuator |

|

| |

Pneumatic Actuator

|

|

|

|

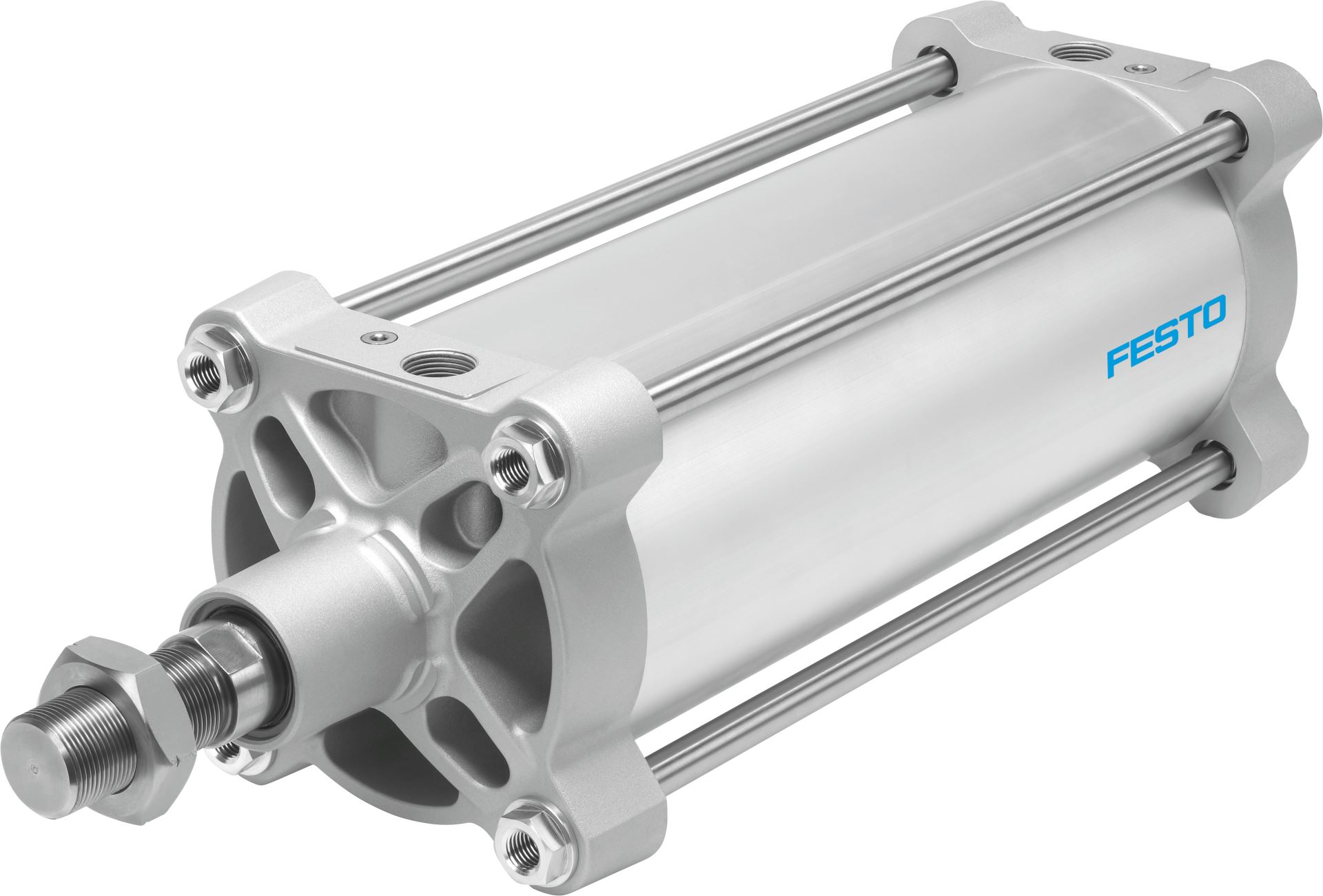

| Pneumatic Cylinder |

|

| Festo pneumatic cylinders are used for executing linear movements, which they can provide thrust forces of up to 50 kN at 6 bar. They are sturdy and flexible thanks to the compressibility of the air, which also makes them resistant to high external forces. Pneumatic cylinders are mainly used in factory automation where force driven application is required. |

|

| Feature models: |

- Round cylinders: DSNU

- Profile cylinders: DSBC, DSBG

- Compact cylinders: ADN, ADVU

- Rodless cylinder: DGC-K, DGC

- Stainless-steel cylinders: CRDNG

|

|

| |

|

|

| Cylinder Sensor |

|

| Festo cylinder sensors are tailor-made to optimize the function for Festo drives. By detecting the magnetic field of permanent magnets installed on the cylinder piston, the position of the piston rod can be detected. |

|

| Feature models: |

- T-slots & C-slots: SMT, SME, CRSMT (corrosion resistant)

|

|

|

|

|

| |

|

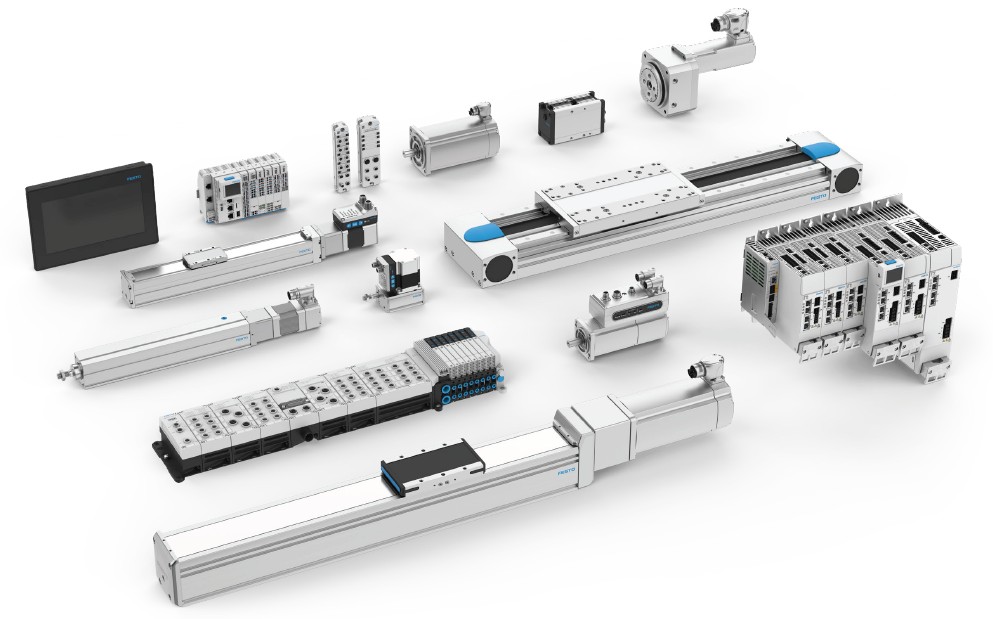

| Electrical Automation |

|

| |

Electrical Automation

|

|

|

|

| Linear axis |

|

| Festo electric axes provides high repeat accuracy and high loads and torques thanks to the design of recirculating ball bearing guide. With various cost-effective model, the electric axes is capable to support various desktop applications. |

|

| Feature models: |

- Spindle axes: EGC-BS, ELGD-BS, ELGS-BS, ELGT-BS

- Cantilever axes: ELCC

- Toothed belt axes: EGC-TB, ELGD-TB, ELGS-TB

|

|

| |

|

|

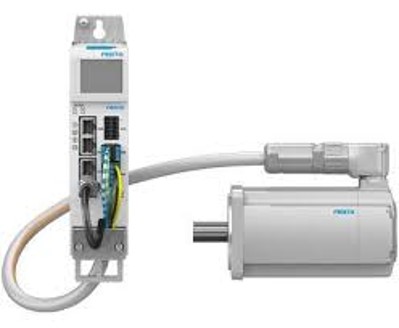

| Servo Drive & Motor |

|

| Festo servo drive & motor form the interface between the mechanics and the controller, which they act as the heart of any motion control system. They provide maximum precision & efficiency, flexibility control and safety features to variety application areas as packaging, medical, assembly industries etc. |

|

| Feature models: |

- Servo drive: CMMT-AS, CMMT-ST

- Servo motor: EMMT-AS, EMMB-AS

- Stepper motor: EMMT-ST, EMMB-ST

|

|

| |

|

|

| Industrial Robot |

|

| Festo industrial robot acts as handling system solution to support automation process such as gripping, positioning, stacking, grouping and indexing. With the help of pneumatic handling module and cartesian robot, Festo gantry robot system ensures precise multi-dimensional movement, faster moving speed and programmable control system for various automated application. |

|

| Feature models: |

|

|

|

| |

|

|

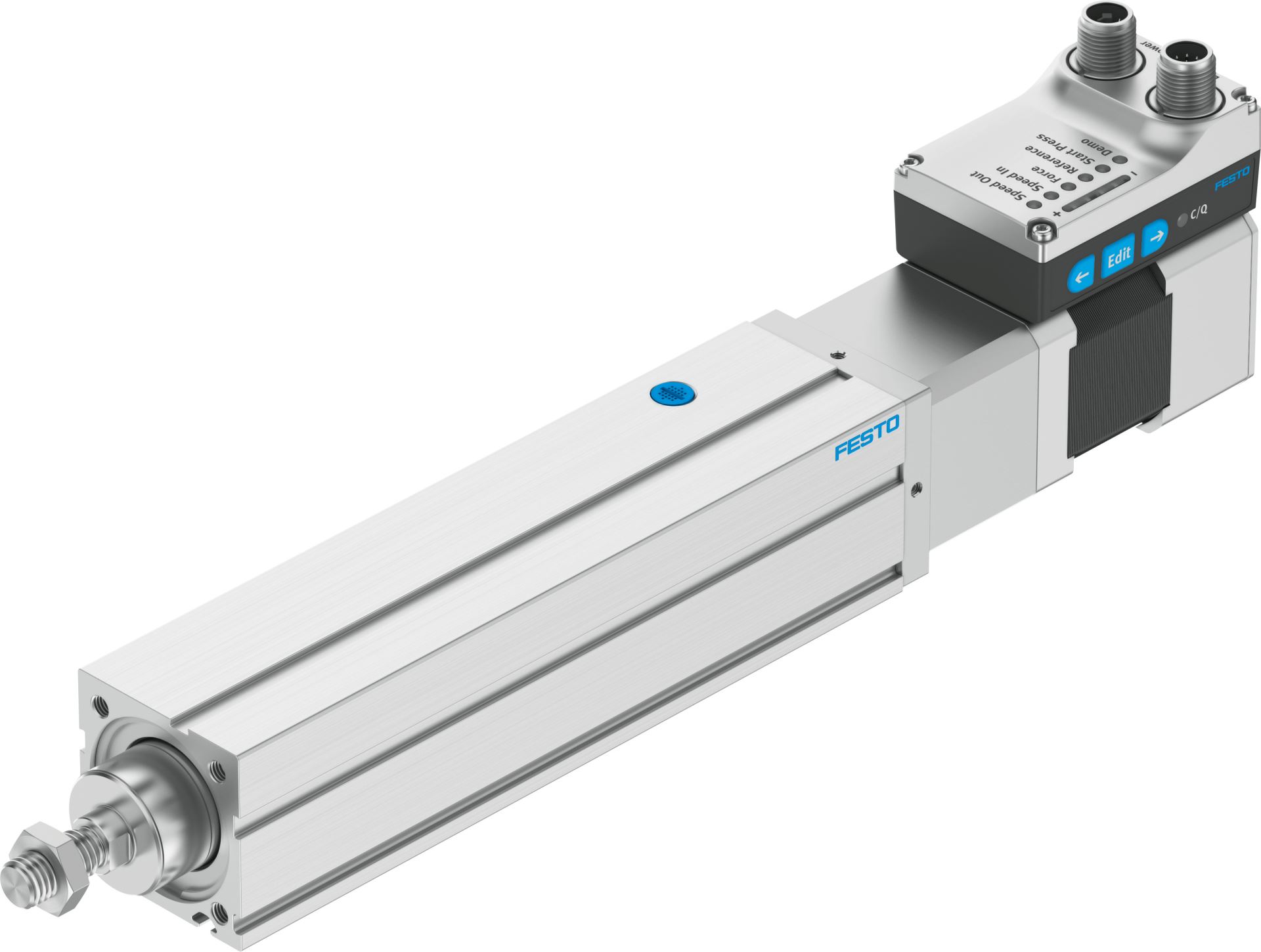

| Electrical Cylinder |

|

| with the help of a servo/stepper motor, Festo electric cylinder performs linear movement similar to pneumatic cylinder. |

|

| Electric cylinder vs Pneumatic cylinder |

- With motor implemented, electric cylinder offers better control and precision to application.

- Electric cylinder is quieter and able to maximize application efficiency by eliminating possible air leakage.

|

|

| Feature models: |

- Electric actuator: EPCS, ESBF, EPCC

- Mini slide: EGSC-BS

|

|

|

|

|

| |

|

|

| Process Automation |

|

| |

Process Automation

|

|

|

|

| Pneumatic & Electrical Valves |

|

| Festo valves can be used on controlling actuators such as cylinders, rodless cylinders, motors or grippers. In addition, we also offer valves for use with valve terminals, depending on the system requirements. |

|

| Feature models: |

- Solenoid valve: VUVS, VUVG, VSNC

- Pneumatic valve: VUWS, VUWG

- Mechanical actuated valve: VHER, VMEF, VHEF

- Flow Control Valve: GRLA, VFOE

|

|

| |

|

|

| Process Valve & Assembly |

|

| Festo process and media valves provide control on fluid process application. Assembly unit consists of actuator, sensor box, positioner and ball valve/butterfly valve controlled by pilot valve can be used for various fluid media. |

|

| Feature models: |

- Butterfly valve/ball valve actuator assembly unit: KVZA/KVZB

- Ball valve: VZBA, VAPB

- Pinch valve: VZQA

- Angle seat valve: VZXA

- Solenoid Media Valve: VZWF

|

|

| |

|

|

| Process Valve Terminal |

|

| Festo valve terminals are commonly used in process and factory automation for automotive and electronics industries, as well as in the pharmaceutical, cosmetics and food and beverage industries. Complying to ISO standards 15407-1, 15407-2 and 5599-2, Festo valve terminals offer versatile valve functions and are available with plug-in or individual connections. |

|

| Feature models: |

- Valve terminal: MPAL-VI, VTUG, VTUS, VTUX

|

|

| |

|

|

| Control Technology & Remote I/O |

|

| Festo control technologies contribute to optimized process operation for better cost efficiencies and improved productivity of the machine. With implementation of operator unit, combination of the technology of pneumatic and electropneumatic ensures consistent program sequence for various application. |

|

| Feature models: |

- Controller: CPX-E

- Remote I/0: CPX-AP-A, CPX-AP-I

- HMI unit: CDPX

|

|

| |

|

|

| Valve Positioner |

|

| Festo valve positioner is designated to pair with semi-rotary drives. The digital feature gives simple but efficient position control for variety of rotary and linear drives. |

|

| Feature models: |

|

|

|

| |

|

|

| Rotary Actuator |

|

| Festo rotary actuator is designated for process valve application. The sturdy, corrosion-resistant design of the actuators is ideal for use in process automation applications in harsh and explosive ambient conditions. |

|

| Feature models: |

|

|

|

| |

|

|

| Energy Saving Service |

|

| Festo offer TÜV-certified energy efficiency analysis of the compressed air system according to DIN EN ISO 11011 by performing leak detection, consumption & wastage analysis and providing energy saving plan to help on plant/line application efficiency. |

|

|

|

|

| |

|

|

| Pneumatic Equipment |

|

| |

Electrical Automation

|

|

|

|

| Tubing, Fitting, Plug & Cable |

|

| Feature models: |

- Festo offer wide range of connection components for pneumatic and electrical applications in various industrial automation.

- Fitting: QS (Straight, elbow, T, Y-shape, multiple distributor), NPQH (Nickel plated), NPQR (SS)

- Plug socket: MSSD (for solenoid coil)

- Connecting cable: NEBA, NEBV, KMF

|

|

| |

|

|

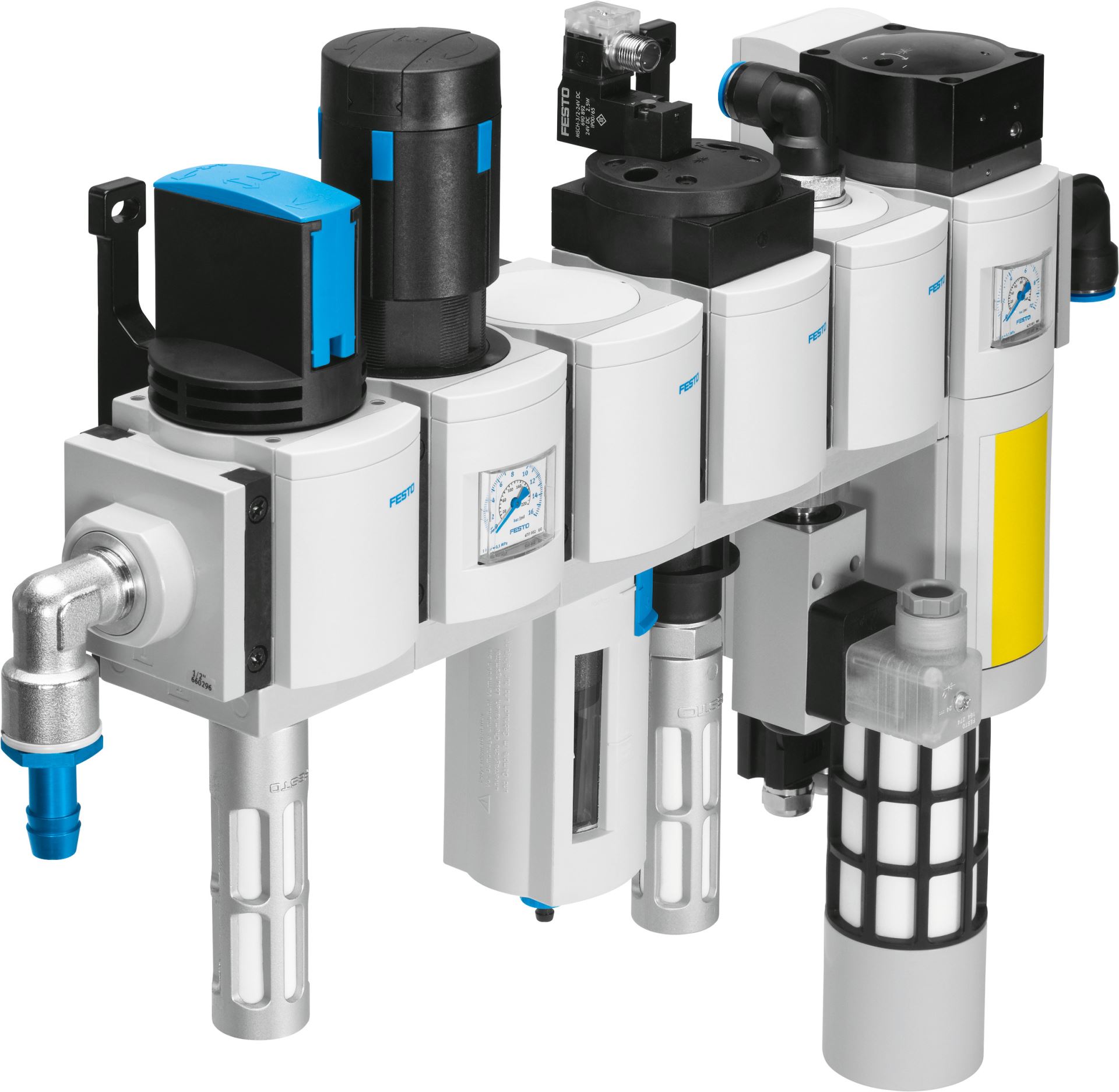

| Filter Regulator |

|

| Festo compressed air service unit ensures the application air quality is optimized by filtering out compressor oil, condensate and dirt particles from the air supply. Festo offer configurable service unit consists of a pressure regulator, filters, lubricator, branching module with pressure switch and exhaust valves for maximum process reliability. |

|

| Feature models: |

- Filter Regulator: MS4/6-LFR, FRL (with lubricator)

- Filter: LF, LFM

- Lubricator: LOE

- Branching module: FRC

- Soft start, on/off valve: SV, EE, EM

- Condensate drain: LWS

- Pressure booster: DPA

|

|

| |

|

|

| Other Sensors |

| Festo offer wide range of sensor for better process control on cylinder, pressure & vacuum and flow application. |

|

| Feature models: |

- Pressure & vacuum sensor: SPAN, SPAU

- Flow sensor: SFAH

- Limit switch box: SRBC (for rotary actuator)

|

|

|

| |

|

|

| Gripper |

|

| Festo gripper system can be operated pneumatically and electrically on holding and positioning workpiece in industrial robot handling systems. |

|

| Feature models: |

- Parallel gripper: DHPC, DHPL, HGPT, HGPL

- Radial gripper: DHRC

- Angle gripper: DHWC

- Swivel/rotary gripper: HGDS, EHMD

|

|

| |

|

|

| Vacuum Generator |

| Festo vacuum generator includes compact and cost-effective which can be used in variety performance levels and different vacuum types (pneumatic & electropneumatic). |

|

| Feature models: |

- Vacuum generator: OVEL, OVEM, VN

|

|

|

|

|